Worldwide Sublimation Distribution

Orca Coatings Best SellersMore...

Light Blue

Light Blue Pink

Pink Yellow

Yellow Mint Green

Mint Green Blue

Blue Yellow

Yellow Grayish Green

Grayish Green Light Pink

Light PinkColor Blank Mug

Blue

Blue Pink

Pink Gray

Gray White

WhiteOthers

Black

Black Brown

Brown Cyan

Cyan Gray

GrayHome & Office

Light Blue

Light Blue Pink

Pink Yellow

Yellow Mint Green

Mint GreenColor Blank Mug

11 oz. Sublimation Two-Tone Stackable New Bone China Coffee Mug

Blue

Blue Green

Green Pink

Pink Yellow

Yellow Blue

Blue Yellow

Yellow Grayish Green

Grayish Green Light Pink

Light Pink Blue

Blue Yellow

Yellow Grayish Green

Grayish Green Light Pink

Light Pink Black

Black Light Blue

Light Blue Light Green

Light Green Barbie Pink

Barbie Pink

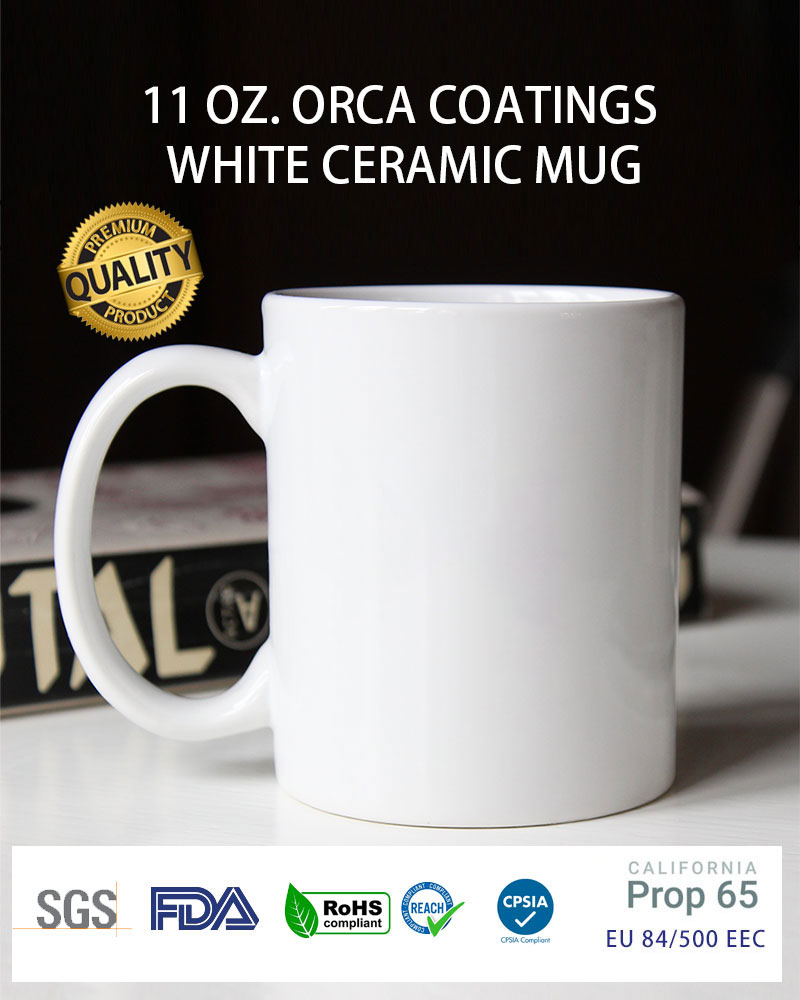

3500+

Cycles Dishwasher Proof

32

Years in Business

150+

Countries

8000+

Products

Video Channel

Best SellingMore...

Black

Black Blue

Blue Green

Green Light Blue

Light BlueClassic Mugs

Green

Green Orange

Orange Pink

Pink Red

RedClassic Mugs

Black

Black Blue

Blue Green

Green Red

RedGet in touch

Be the first to know about our latest product releases, hot-selling recommendations, exclusive offers, and more!

Blog

About Orca Coatings.com

Founded in 1992, Photo USA has become the leading manufacturer of dye-sublimation ceramics and a full range of dye-sublimation image products. We develop and sell products to be processed with dye-sublimation presses, dye-sublimation presses to create high-quality ceramic images, and the full range of sublimation machines and raw materials for making high-quality ceramic products. We have utilized our 31 years of experience to bring you the best coating on the market.

In addition to the high quality of our sublimation printing process, Photo USA offers ORCA coatings on all of our products. ORCA is the highest standard in the industry; with it, we guarantee a consistently superior line of products. Photo USA supplies the industry with stainless steel, aluminum, glass, and fabric substrates as well as sublimation equipment and supplies.

Know More...